by Chintan Sheth, Mechanical Engineer, PMP, Brookhaven National Laboratory

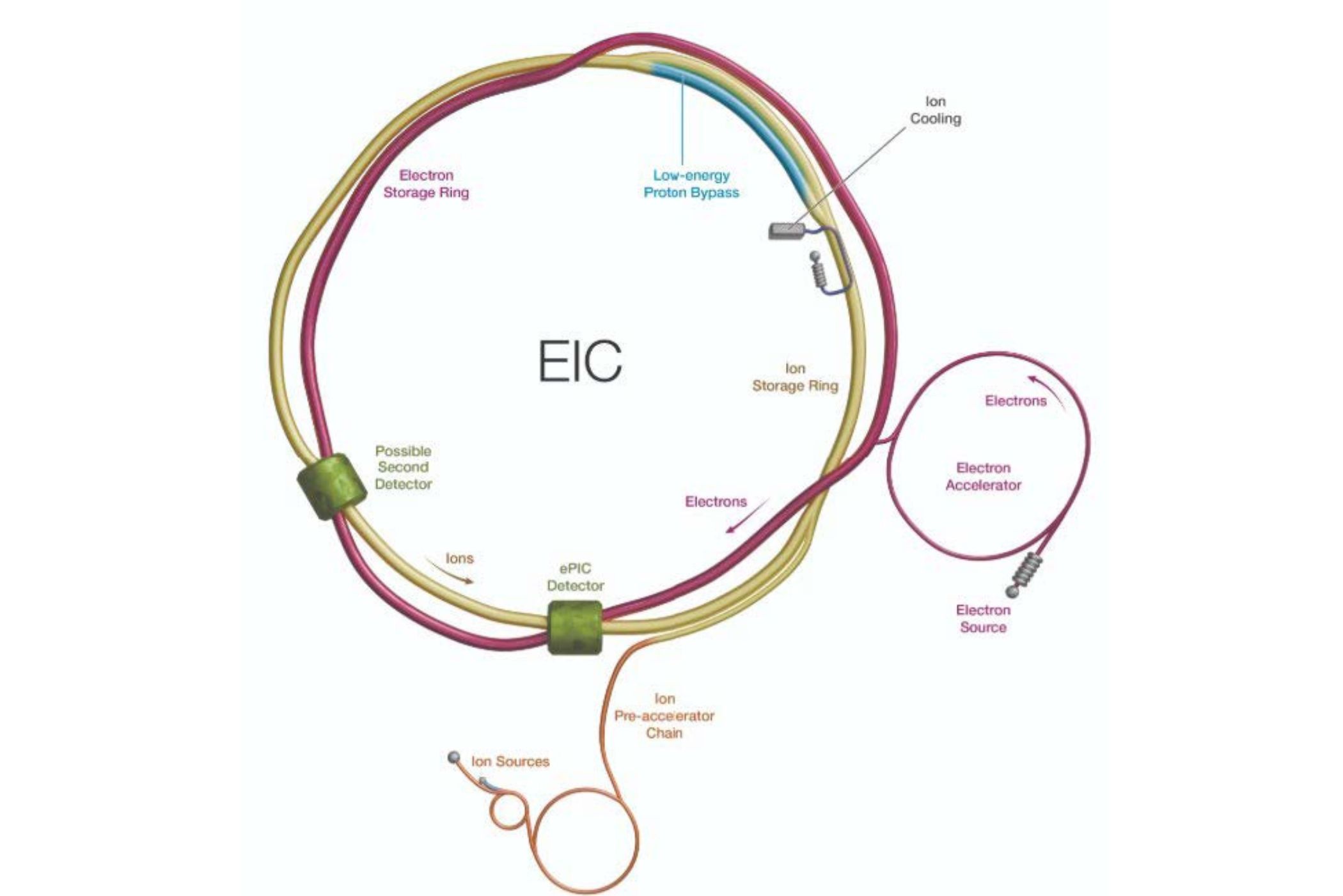

The Relativistic Heavy Ion Collider (RHIC) has been running successfully since the year 2000 at the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory (BNL). 2025 will be RHIC’s final run, and the facility will be decommissioned after the run ends in December 2025. The existing infrastructure will then serve as the foundation for the Electron-Ion Collider (EIC), a first-of-its-kind facility designed to enable high-precision studies of the internal structure of protons and nuclei.

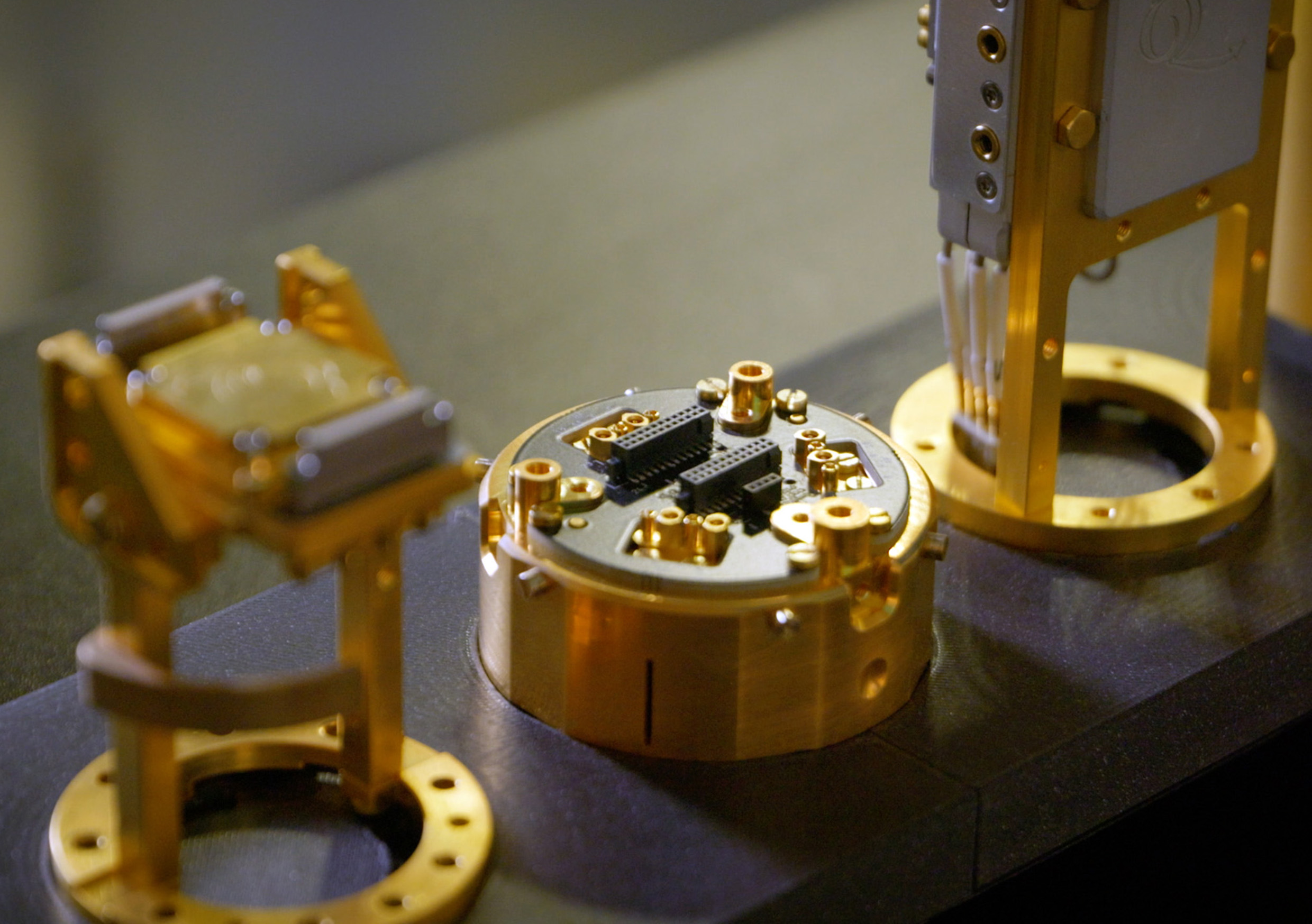

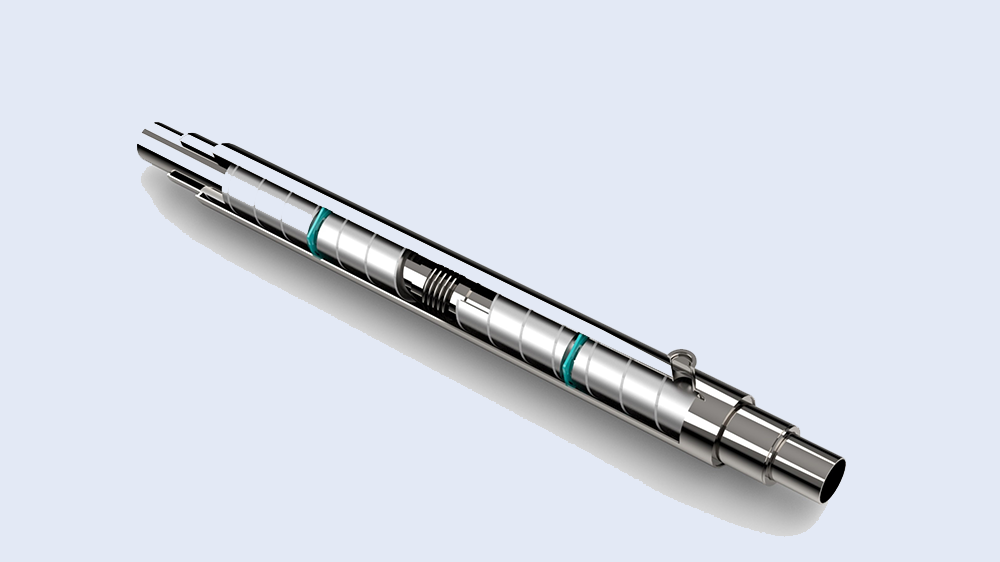

The RHIC-to-EIC transition will require removal of the existing “Blue” magnet ring and beam line from the tunnel and modifications of many portions of the “Yellow” magnet ring. Additionally, a new electron storage ring (ESR) will be installed in the tunnel to circulate the electron beam, enabling collisions between polarized electrons and ions at designated interaction points, including the future ePIC detector. One major modification will involve installing high-power superconducting radio frequency (SRF) cavities, which are used for energy recovery and to accelerate charged particles to very high energies with high efficiency. Each SRF cryomodule houses one or two SRF cavities, allowing for optimized thermal insulation, efficient cryogenic cooling and streamlined integration into the accelerator beamline, while maintaining the high-field stability required for particle acceleration.

These cavities are being produced at DOE’s Thomas Jefferson National Accelerator Facility, where they will be tested at half-power capacity. Then they will be shipped to BNL and tested at full-power capacity before being installed inside the EIC tunnel. This testing will ensure that no damage occurred to the sensitive components — such as high-power couplers, tuners, cryo lines and RF connections — during their travel. Since it is a mammoth task to remove cryomodules and cavities from inside the tunnel, it’s crucial to verify that these will perform as per their design prior to installation. To support this effort, BNL has designated a facility, the Horizontal Test Facility (HTF), for conducting these high-power tests. This article presents the cryogenic upgrades required within and around the HTF to successfully support the testing of these vital SRF components.

The scope for this upgraded HTF will be to enable high throughput (1-2 tests per month), multi-frequency, long-term 2.0 K testing capabilities for the EIC project and for BNL in general. The diagram in Figure 2 gives a cryogenics perspective of how new and existing cryogenic equipment is coming together to satisfy testing needs of these cavities.

Purple-colored equipment signifies new procurements. Black-colored equipment already exists and is located in the building near the HTF. Green-colored equipment is currently being utilized for RHIC operations and will be brought in after the final RHIC run ends.

As seen in the diagram, there is currently an existing Helium Liquefier with a liquification capacity of 2 grams/sec that produces inventory in the existing 3,500-liter helium dewar. Procurement of a new helium liquefier from Air Liquide (Helial 280) with liquification capacity of 10 g/sec is underway, along with a new 3,500-liter helium dewar from Wessington Cryogenics that will have a subcooler coil. Warm helium gas supply comes in from the outside 46,000-gallon warm helium tank that is also connected with the RHIC gas tank farm for additional inventory and inventory management. A recently installed liquid nitrogen cooled purifier loop uses a pair of open neck purifiers to help clean the “dirty” gas in the warm helium tank and from the sub-atmospheric warm helium pumps. Procurement of a new 85 g/sec purifier will significantly upgrade the capacity to clean helium in future.

The top view of the facility can be seen in Figure 3. Existing equipment is in black boxes; new procurements are in purple boxes, and green box equipment is currently being used for RHIC operations.

The different SRF cavities are in various design phases. There can be single or a dual SRF cavities inside a cryomodule. The goal of this cryogenic equipment upgrade is to fulfill the test requirements provided by the RF group. Based on their initial design and estimates, Table 1 shows the preliminary heat load estimate for a cryomodules carrying two RF cavities under full high power with a cryogenic valve box.

The RF group plans on simultaneously operating one cryomodule under full power (static + dynamic) and the second cryo-

module under static power only. Based on these requirements, the Cryo group has come up with preliminary liquid helium usage estimates shown in Table 2.

Since the new helium liquefier produces 10 g/sec of liquid helium, the existing liquefier with 2 g/sec will also need to be running if the test load remains above the new liquefier capacity for an extended amount of time. The new 3,500L liquid helium storage dewar for the new liquefier will have a subcooler built in to utilize the inventory for capacity assist when the load exceeds the liquefier capacity. Inventory from the existing dewar can be transferred to the new dewar via an interconnecting liquid helium jumper line if required.

In coming months, the Cryo group will work on finalizing the design of the cryo distribution from the liquefier to the valve boxes that will feed the SRF cryomodules located inside the HTF. The HTF combines the use of existing cryo equipment, repurposed RHIC cryo-systems equipment, and new equipment being procured to minimize cost while meeting the RF test requirements.

Acknowledgments:

This work is supported by Brookhaven Science Associates, LLC under Contract No. DE-SC0012704 with the U.S. Department of Energy.

Yatming (Roberto) Than (Deputy C-AD Cryogenics): Cryogenic calculations and system requirements

Jennifer Maceiko (Piping Designer) and Cliff Britus (Mechanical Engineer): 3D CAD Modeling Support