by Crane Communications

Crane Cryogenics, a division of Crane ChemPharma and Energy, has built its reputation by delivering reliable high-performance solutions for some of the most demanding cryogenic environments in the world. The company designs and manufactures advanced vacuum jacketed piping, valves and fittings that enable the safe and efficient transfer of liquefied gases such as hydrogen, nitrogen, oxygen, argon and liquefied natural gas.

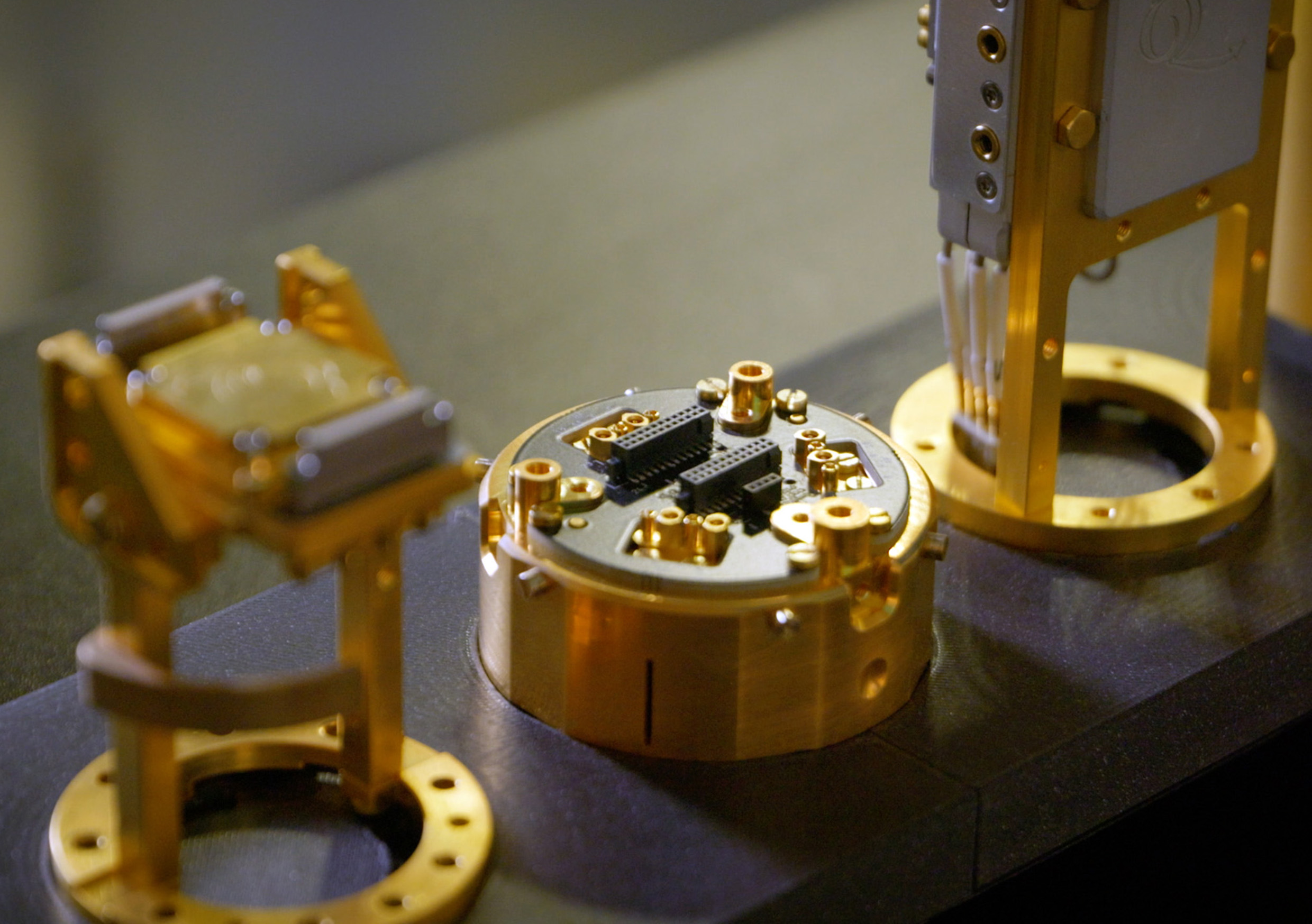

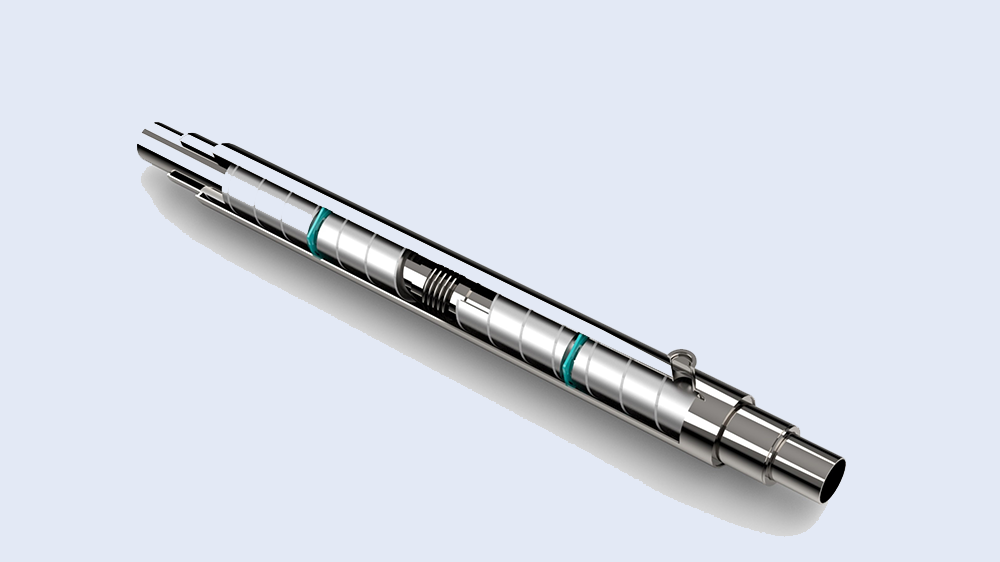

The foundation of Crane Cryogenics is its engineering heritage. The company draws on more than a century of experience from Crane’s long history in valve design, materials science and process control. This depth of experience allows it to apply proven mechanical principles to new challenges in cryogenic technology. Whether in a laboratory setting, an energy facility or an aerospace environment, Crane’s products are developed to meet the highest standards of safety, purity and efficiency. The company emphasizes that cryogenic systems must maintain reliability and performance in extreme temperatures where even small fluctuations can affect pressure integrity and operational safety. Its vacuum jacketed piping systems are specifically engineered to minimize heat transfer, prevent leaks and ensure stable operation. Every component from fittings to globe valves is built with longevity and repeatability in mind.

As Crane explains in its technical materials, success in cryogenic service depends on understanding both the mechanical and thermal demands of low-temperature fluids. This dual expertise allows Crane Cryogenics to offer complete end-to-end solutions serving industries that rely on consistent cold performance for their processes.

One of the fastest-growing areas of focus for Crane Cryogenics is the hydrogen sector. As global industries shift toward cleaner energy sources, hydrogen has emerged as a promising alternative to fossil fuels but its safe handling requires specialized infrastructure. Crane has positioned itself as a key contributor to this emerging field.

The company provides cryogenic pipe, valve and fitting systems that serve the full hydrogen lifecycle: production, liquefaction, transportation, transfer and storage. Its vacuum-insulated technologies and bellows-seal valves ensure that hydrogen remains at cryogenic temperatures while minimizing the risk of leaks or thermal losses. These systems are designed to handle the unique challenges of hydrogen, including its small molecular size and high permeability.

On its hydrogen applications pages, Crane Cryogenics highlights the importance of integrating advanced PVF (pipe, valves and fittings) technologies across every step of the hydrogen supply chain. The company’s engineers collaborate with customers to develop systems that not only meet regulatory standards but also improve efficiency and safety in day-to-day operation. Crane’s work also extends to liquefied natural gas and other industrial gases used in chemical processing, energy storage and transportation. By applying its deep cryogenic expertise to these sectors, the company contributes to a broader energy transition that depends on secure low temperature infrastructure.

In addition to energy-related projects, Crane Cryogenics has supported a growing number of installations in the life sciences. A recent feature on the company’s website described how its engineers have guided biological laboratories and cryogenic storage facilities toward more effective use of liquid nitrogen systems. These systems help preserve biological samples and pharmaceutical materials while improving efficiency and reducing losses due to boil-off. Across each of these industries, the company’s goal remains the same: to provide confidence that cryogenic systems will perform safely and consistently even under the most demanding thermal and mechanical stresses.

Crane Cryogenics approaches its work with a focus on collaboration and problem-solving. Many of the company’s recent updates highlight how it partners with customers to tailor cryogenic solutions to unique operating conditions. Its engineers emphasize lifecycle performance, reliability under thermal cycling and ease of maintenance.

The company’s testing and validation programs ensure that each product line performs as expected across years of use. Materials are selected for durability and compatibility with cryogenic fluids and every design is supported by rigorous quality control. These efforts reflect Crane’s philosophy that cryogenic technology is not just about surviving extreme temperatures but about enabling systems to function with precision and predictability. Crane Cryogenics also invests in education and outreach within the cryogenic community. Through its participation in conferences and publications, it shares insights on best practices for hydrogen storage, vacuum insulation and valve design. The company’s engineers often discuss the importance of proper material selection, clean assembly practices and long-term maintenance planning for cryogenic systems.

Crane Cryogenics advances precise, reliable solutions that bridge traditional industries with the emerging hydrogen economy and sustainable energy systems. Its commitment to technical excellence and customer needs supports cleaner energy development and the scientific progress that depends on cryogenic technology.

http://www.cranecpe.com