by Excel Loading Systems Communications

Since its establishment in 2013, Excel Loading Systems has rapidly emerged as a leading manufacturer of advanced loading arm systems, particularly excelling in cryogenic applications. Specializing in the safe and efficient transfer of liquefied gases such as LNG, liquid nitrogen, liquid oxygen and hydrogen, Excel has become a key partner for industries requiring precise and secure fluid handling.

The company’s cryogenic loading arms are engineered to operate at extreme temperatures, as low as -196°C (-320°F), allowing the safe transfer of liquefied gases between storage tanks and transport vehicles, including ships, railcars and tank trucks. Maintaining mechanical integrity under such harsh conditions requires specialized materials, careful engineering and attention to operational safety. To meet these demands, Excel constructs its loading arms from stainless steel and nickel alloys, materials that resist embrittlement and corrosion while retaining strength at cryogenic temperatures.

The arms themselves feature articulated joints that provide flexibility and allow smooth movement during loading and unloading. Balancing systems using counterweights, hydraulic cylinders or spring mechanisms help operators maneuver these arms with minimal effort, even in extreme cold where manual handling would otherwise be difficult. These design elements are essential for industries such as LNG export and import terminals, industrial gas production facilities and the space sector, where handling liquefied gases safely and efficiently is critical.

A cornerstone of Excel’s innovation lies in its precision-engineered swivel joints, including models such as the XL-1.0 and the high-pressure XL2.0HP. These components are critical to the performance of cryogenic loading systems, providing flexibility and smooth motion while maintaining leak-proof connections. The high-pressure swivel joints incorporate hardened ball races and corrosion-resistant seal faces to ensure long-term reliability and minimal maintenance. They allow the arms to handle not only standard cryogenic liquids but also pressurized and high-volume flows, which is particularly important for industries that demand both speed and precision in fluid transfer. Swivel joints are often the determining factor in system reliability, and Excel’s commitment to engineering excellence ensures these components meet or exceed industry standards.

Safety is another central focus for Excel Loading Systems. Cryogenic fluids present unique hazards, including the risk of vaporization, rapid expansion, and fire and frostbite, making robust safety systems essential. Excel addresses these risks through emergency release systems and breakaway couplings, which allow the arms to disconnect automatically if a vehicle moves unexpectedly or if excessive tension is applied. Both ends of the connection seal upon disconnection to prevent spills and protect personnel.

Temperature sensors are integrated throughout the arms to provide real-time monitoring of the fluid during loading and unloading, and emergency shutoff valves and fire and gas detection systems provide additional layers of protection. Operators are trained and equipped with personal protective equipment such as cryogenic gloves, face shields and insulated clothing, all of which contribute to safe operation in extreme environments.

Excel also distinguishes itself through its commitment to quality and service. All standard swivels, elbows, pipes and spring components are manufactured in the United States, ensuring traceability and strict adherence to quality standards. The company provides rapid shipping and expedited delivery options, often outperforming competitors in lead times and offers in-field replacement, adjustment and factory refurbishment services to maintain operational continuity. This combination of engineering, manufacturing excellence and responsive service reinforces Excel’s reputation as a reliable partner for industries that rely on cryogenic processes.

Applications of Excel’s cryogenic products are diverse and critical. In LNG terminals, their loading arms facilitate the safe and efficient transfer of liquefied natural gas between storage tanks and cargo ships. In industrial gas facilities, they handle large volumes of liquefied nitrogen, oxygen or argon for production, storage and distribution. In the space industry, Excel’s equipment supports the fueling of rockets with liquid oxygen and hydrogen, where reliability and safety are paramount. Across these applications, Excel’s products are designed to maintain the integrity of the fluid, prevent leaks and ensure the safety of operators and infrastructure.

Through continuous innovation, attention to material selection, engineering precision and a strong focus on safety, Excel Loading Systems has become a benchmark in cryogenic fluid transfer solutions. Their products combine durability, flexibility and reliability to meet the stringent requirements of some of the world’s most demanding industries.

By delivering high-quality cryogenic loading arms and swivel joints, along with exceptional service and support, Excel ensures that liquefied gases are transferred safely, efficiently and reliably, solidifying its position as a trusted leader in the field. /www.excelloading.com/

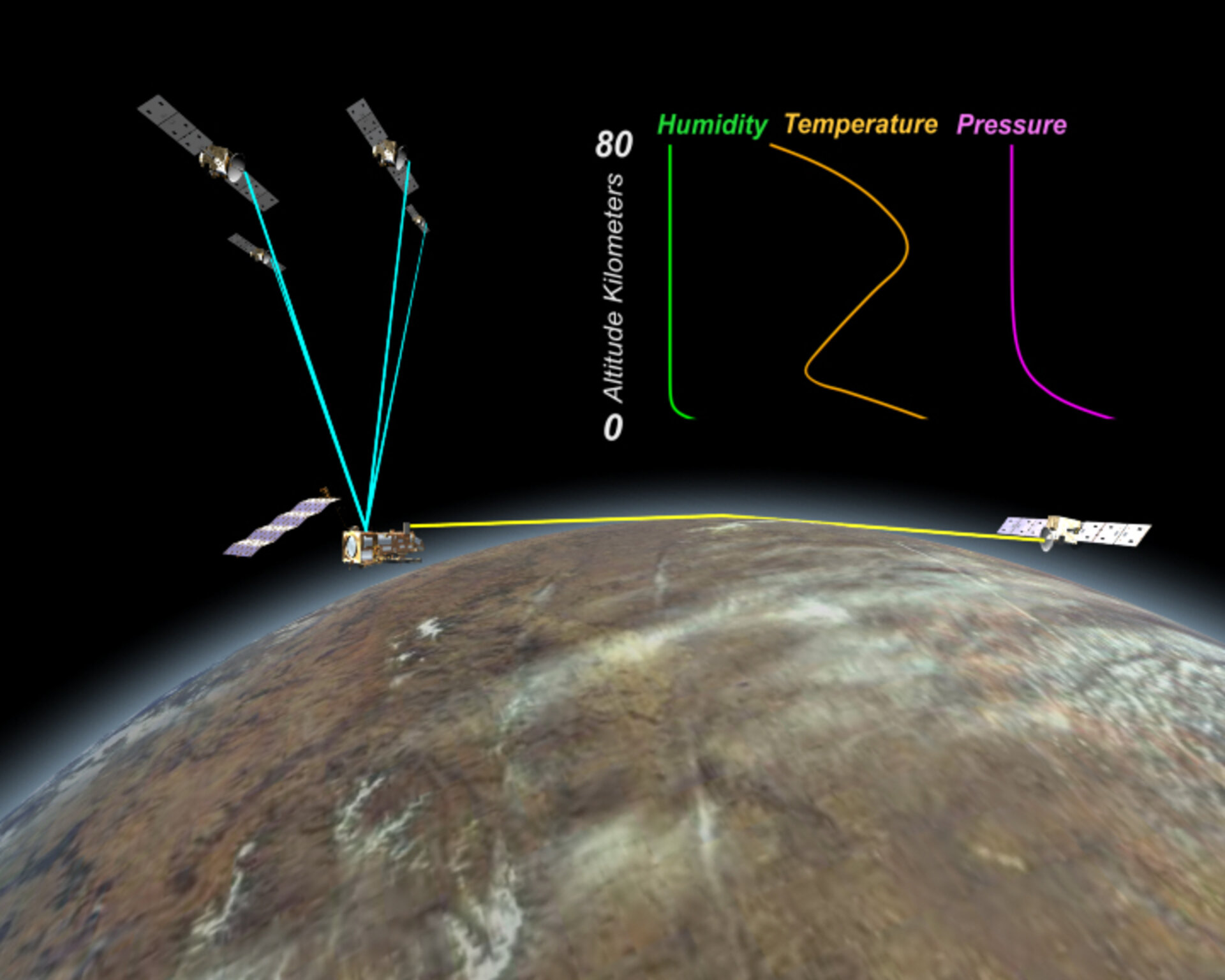

Image: Excel loading swivel breakdown. Credit: Excel