Messer’s Freezing and Chilling Solutions Take the Cake, and Cool It Too

Author: Messer Americas

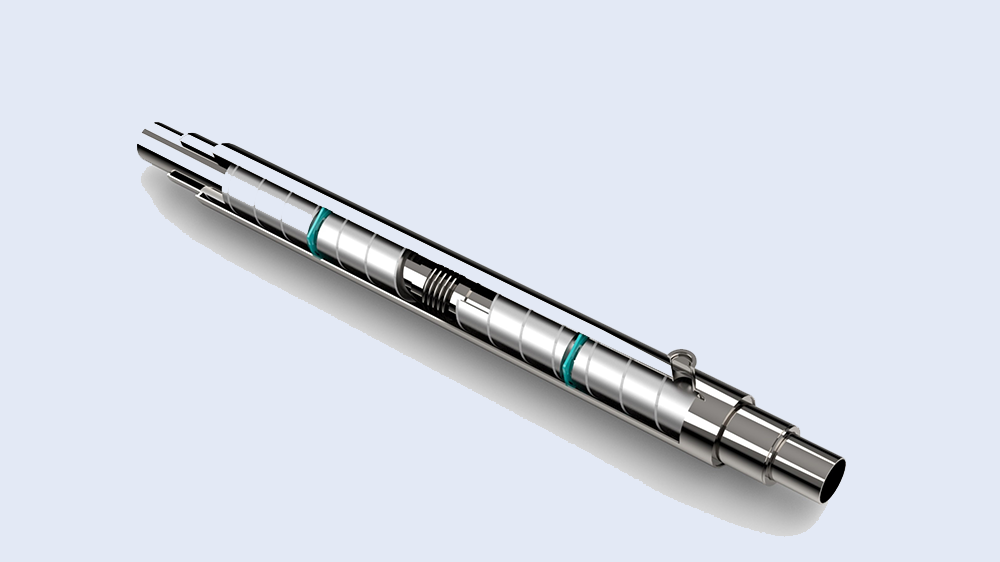

Messer, a leader in cryogenic temperature control solutions, showcased the KwikChiller in an exclusive Innovation Suite at the 2025 International Baking Industry Exposition (IBIE). The technology was presented as a high-throughput cooling and freezing solution designed for bakery and prepared-food products, combining a compact footprint with the ability to preserve product quality.

The KwikChiller addressed a long-standing challenge in the baking and prepared foods industries: increasing production capacity without compromising texture, appearance, or overall quality. By combining a continuous operational design with precise cryogenic control, the system enabled processors to scale efficiently while protecting delicate products.

“Bakers and processors have long sought a reliable way to maintain product quality while scaling up their operations,” said Don Smiley, Director of Food and Beverage at Messer. “With the continuous operational design and compact footprint of the KwikChiller, processors can rapidly cool or freeze delicate or texture-sensitive products while simultaneously boosting throughput.”

Cryogenic solutions continued to play an increasingly critical role in modern food production, particularly as manufacturers faced growing demand, tighter production schedules, and evolving consumer expectations. Messer’s freezing and chilling technologies were engineered to deliver consistent, repeatable results across a wide range of applications.

Why Cryogenic Solutions Matter for Baking and Beyond

Cryogenic freezing and chilling systems offered several advantages for bakeries and prepared-food processors, including versatile product handling, increased productivity, and precise temperature control. Messer’s solutions supported a broad range of baked and prepared foods, from cakes and pies to burritos, pizzas, and premium snacks. Cryogenic and cryo-mechanical deployments helped increase throughput, add supplemental cooling capacity, and reduce production bottlenecks.

Variable-rate cooling protected delicate or texture-sensitive products, helping preserve moisture, structure, and overall quality. High-capacity cooling and freezing were achieved within a compact equipment footprint that integrated easily into existing process lines.

During IBIE, Messer invited attendees to visit Booth #3255 in Las Vegas, Nevada, where the company’s food industry team engaged with processors to discuss production challenges and demonstrate its portfolio of freezing and chilling solutions. An Innovation Showcase image featuring the Messer logo was also displayed as part of the exhibit experience.

Messer also offered an exclusive, appointment-only tour of its Innovation Suite, providing attendees with a closer look at the KwikChiller and other innovations. The tours gave participants an opportunity to explore how Messer’s cryogenic technologies could support high-performance food production environments.

Source: https://www.messeramericas.com